- Manufacturing

- EPIQ

-

Technology

- Overview

- Technology

- SmartWire

- Cells

TECHNOLOGY

-

Solar Solutions

- Overview

- Residential

- Commercial

SOLAR SOLUTIONS

- Company

- Downloads

The world’s most advanced

cell connection technology

The Latest Process

for Solar Cell

Interconnection

SmartWire Connection Technology (SWCT®) is a revolutionary cell connection process for solar module manufacturing. Standard busbars are replaced by 18 micro-wires that gather energy more fluently and strengthen the cells. SWCT®’s superior performance results in advanced module efficiency while negative effects are significantly reduced.

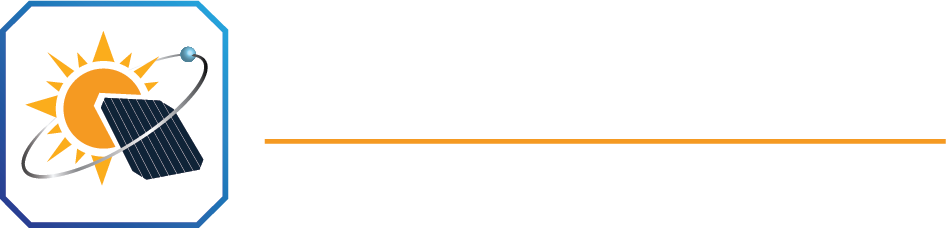

Foil-Wire

Electrical Conductor

The 18 micro-wires are robotically positioned in parallel and held in place by a transparent foil in an over/under pattern. This foil-wire assembly (FWA) forms the electrical conductor, designed with surgical precision, to interconnect the solar cells and eliminate the need of busbars.

Automated Cell

Connection

The solar cells are linked robotically with the FWA to form a cell string, eliminating the busbar to cell soldering process. The FWA interconnects the front side of a cell to the back side of the next cell, ensuring the proper connection from cell to cell.

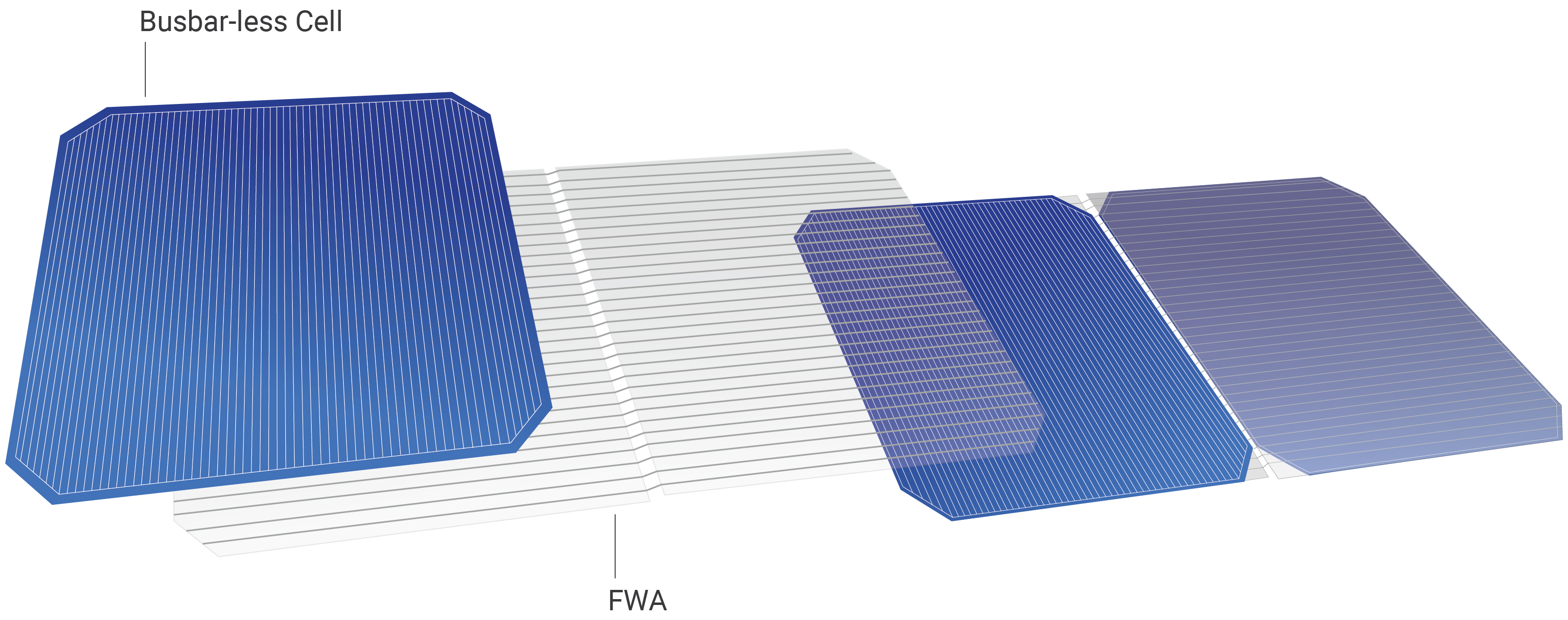

Matrix Creation

& Layout

A 60 cell solar matrix is created by alternating 6 strings of 10 cells. The matrix is covered with encapsulant then placed between a sheet of glass and a backsheet.

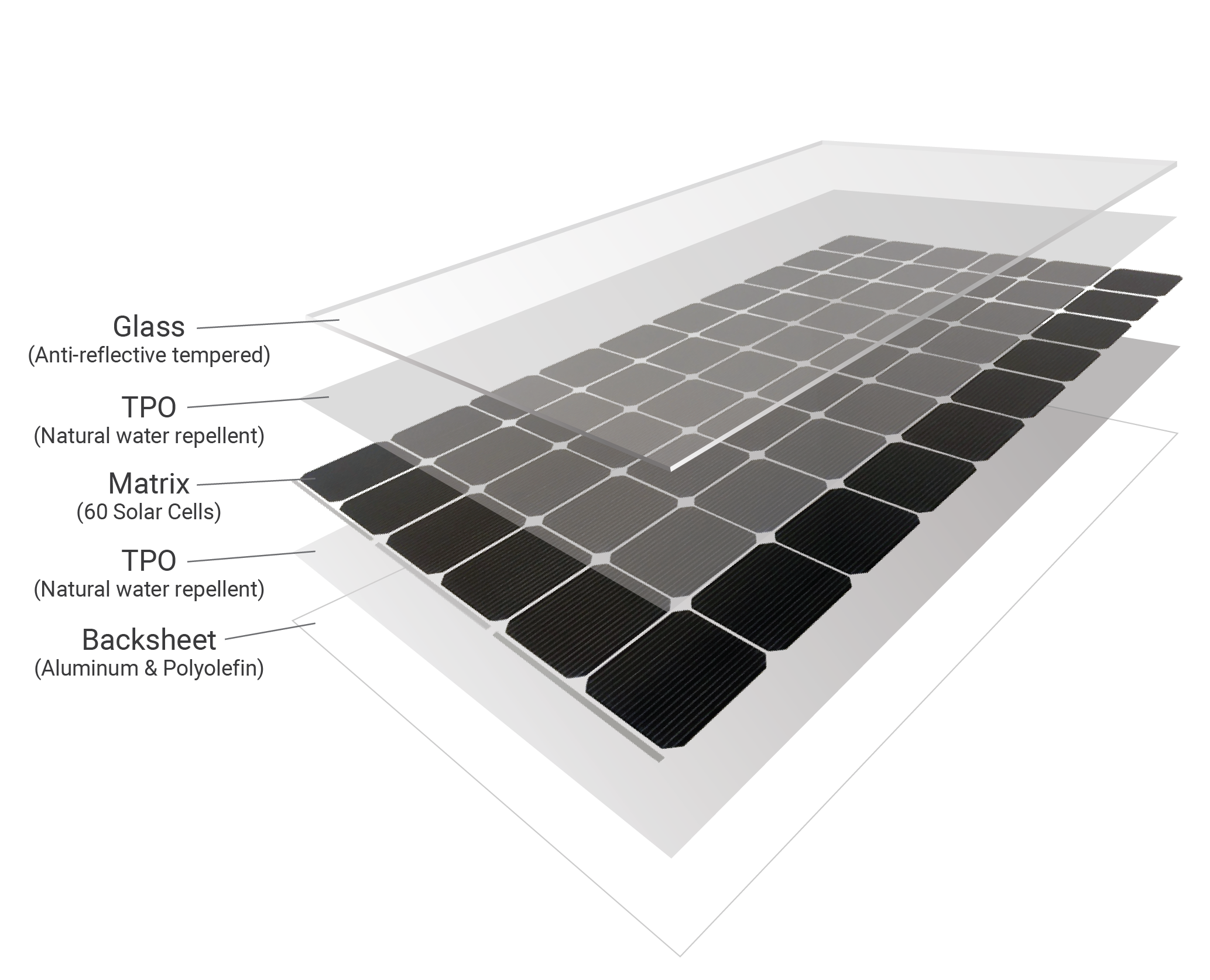

Lamination And

Electrical Contact

In order to protect the cell matrix from environmental influences, the individual layers are bonded together by vacuum pressure and heat, to form an ultra durable solar laminate. This lamination process also forms the electrical connections between the wires and the cell.

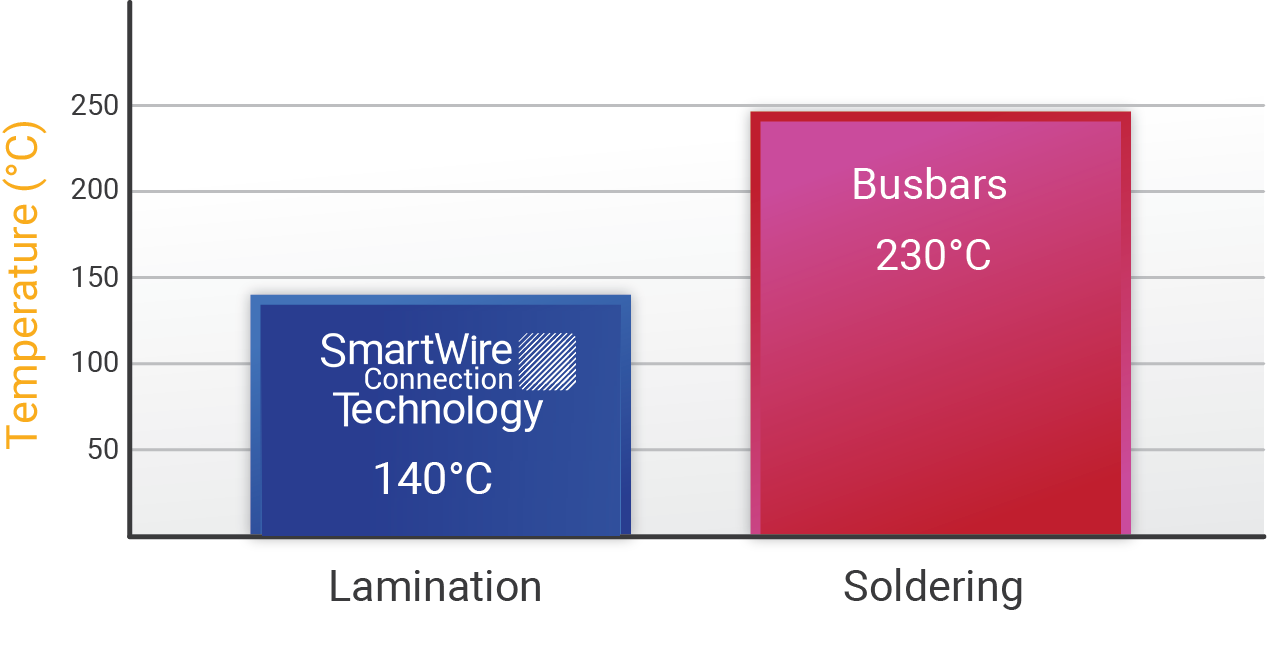

Low Temperature Bond

The SmartWire to cell connection points are bonded at a lower temperature than the busbar soldering process. As a result, SWCT® induces less thermo-mechanical stress on the solar cell, significantly reducing the cell brittleness associated in busbar technology.

Advanced Energy

Collection

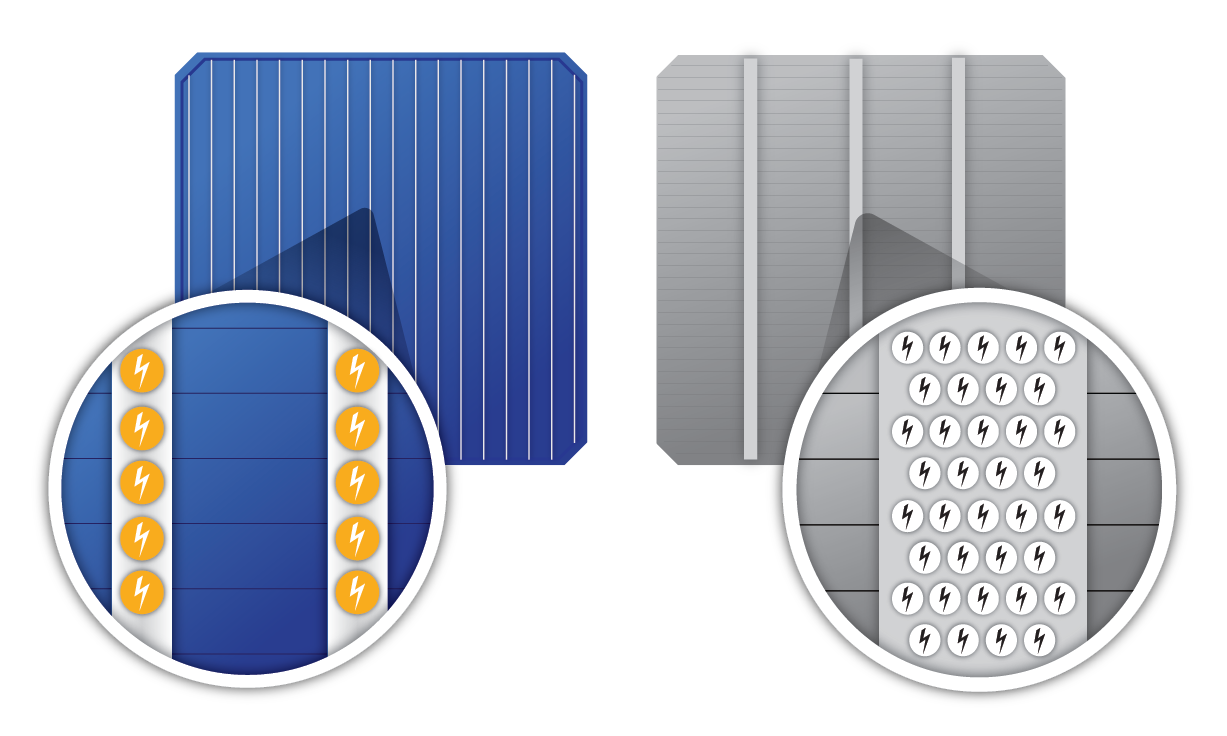

The superior efficiency of SWCT® is driven by 18 micro-wires that form a dense grid of up to 2,660 contact points on the solar cell. This structure allows electrons to travel a shorter distance in order to be collected, thus reducing resistive losses.

Lower Resistance = More Electricity

Higher Resistance = Less Electricity

The lower resistance enables the extraction of more power from each individual finger, thereby increasing the power density when compared to traditional busbar panels.

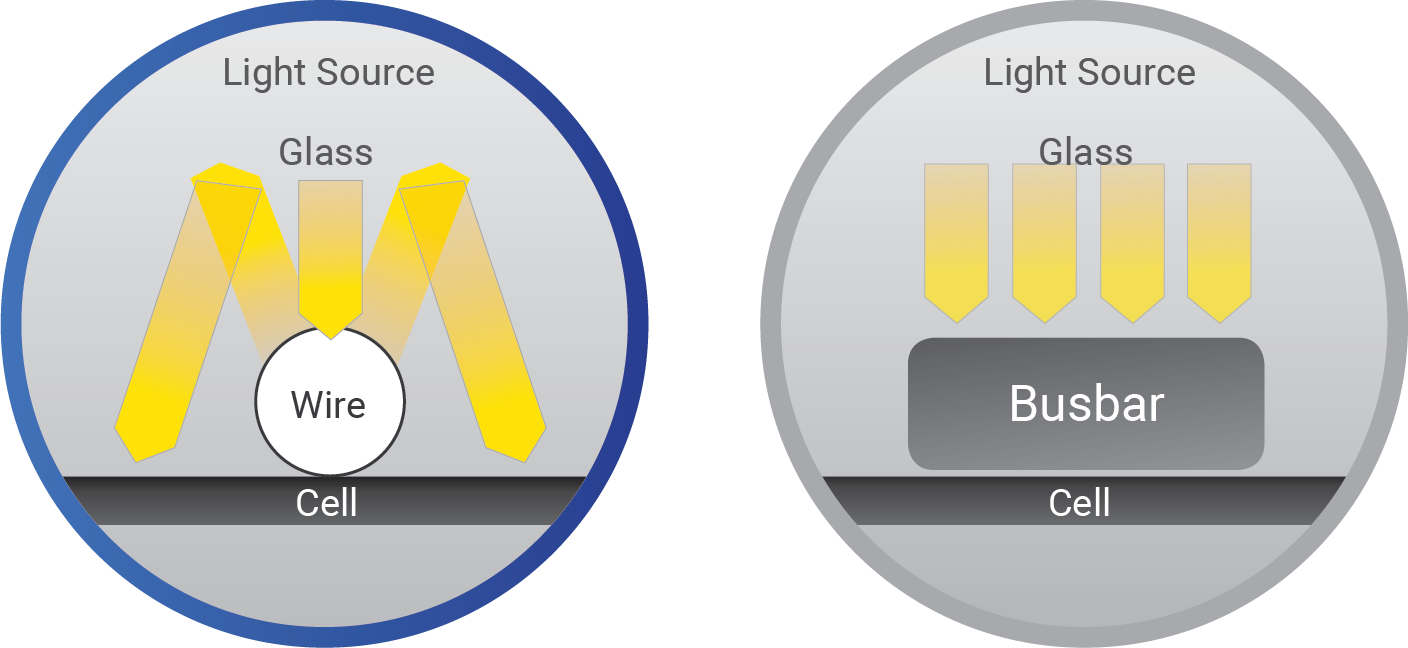

Redirecting Light

The round shape of the micro-wire introduces a light trapping effect which reduces the shading by 25% compared to busbar technology.

Busbars

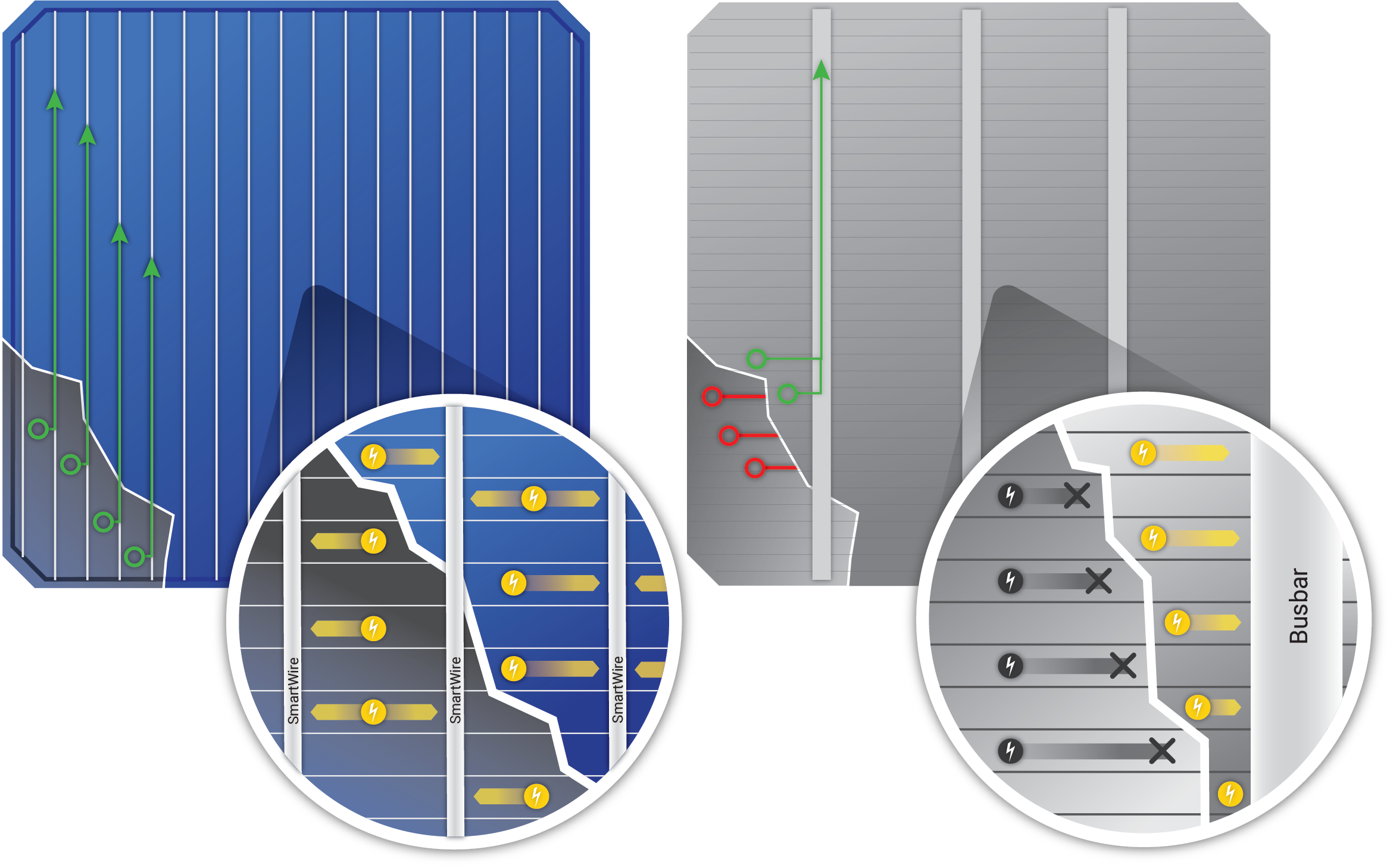

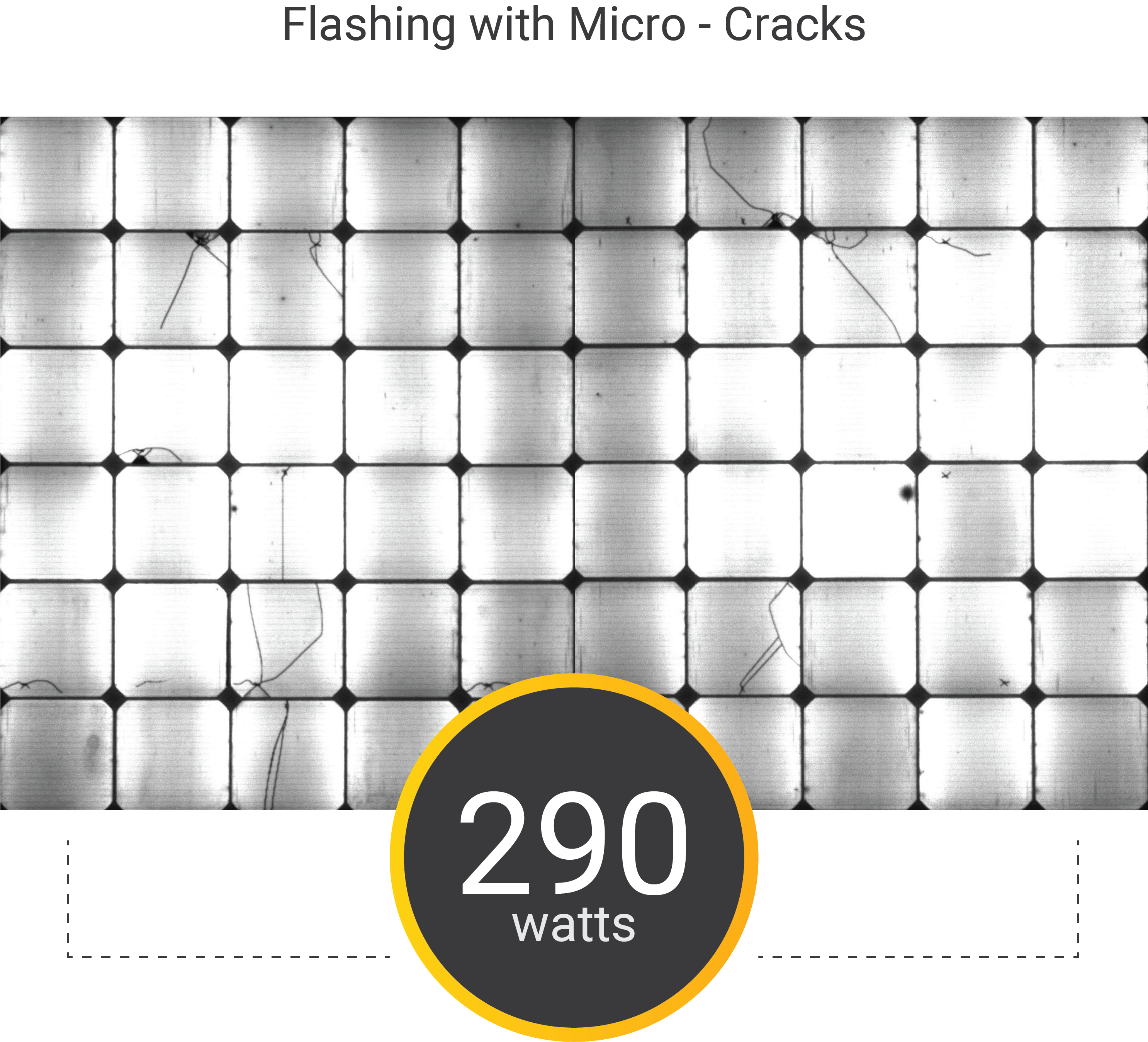

Minimizing Micro-Crack Effects

Micro-cracks have a minimum effect on modules with SmartWire, since the FWA acts as a protective layer for the solar cell with the dense grid of up to 2,660 contact points. Even a micro-cracked cell remains contacted, maintaining the energy collection at high levels.

Busbars

View & download the

Superior Energy

Performance

EPIQ photovoltaic modules offer world class performance by utilizing next-generation SmartWire Connection Technology. This innovative method of interconnecting solar cells maximizes performance for decades to come.

SmartWire Connection Technology Menu

Module Performance

Warranty

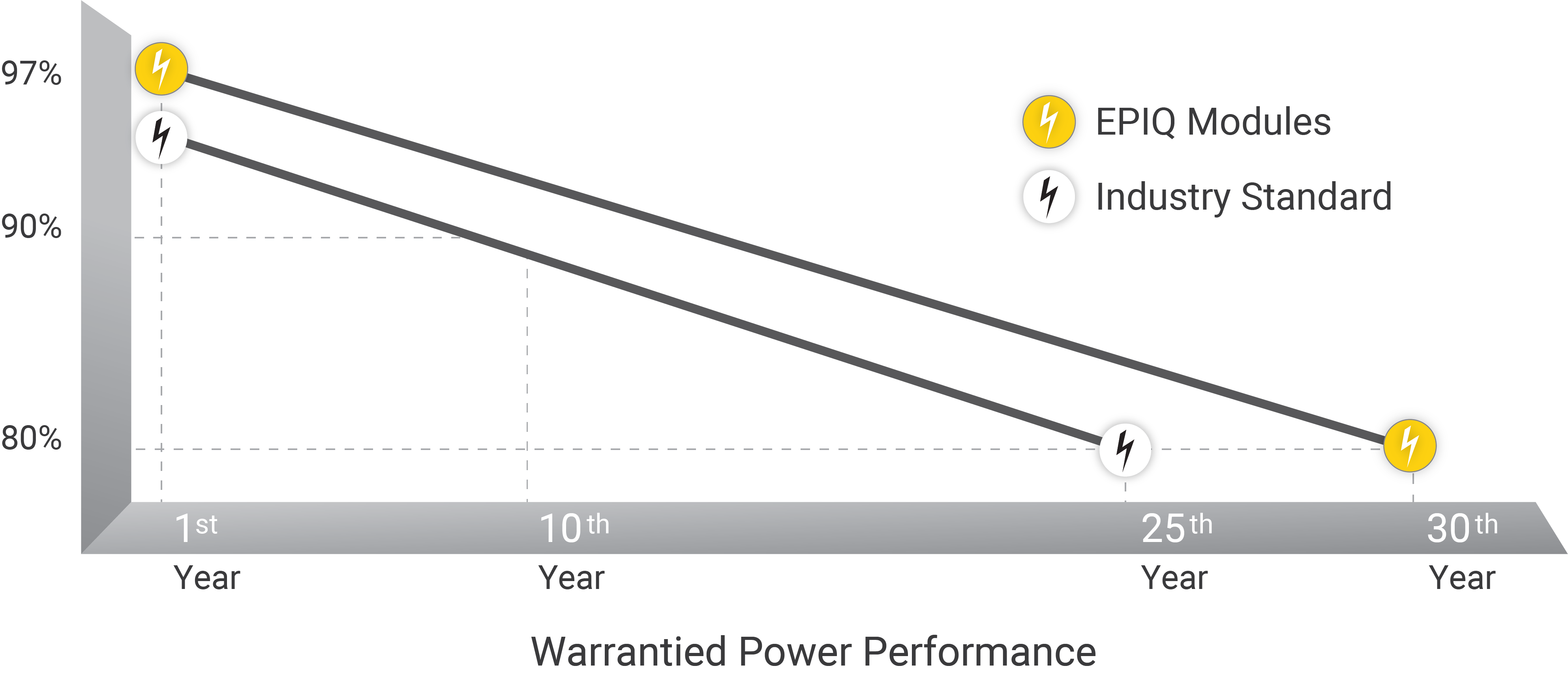

EPIQ PV modules are backed by our industry leading 30-year performance warranty. By combining the most advanced materials and the automated SmartWire manufacturing process; SolarTech Universal delivers premium panels of unrivaled performance.

Performance Under

Extreme Conditions

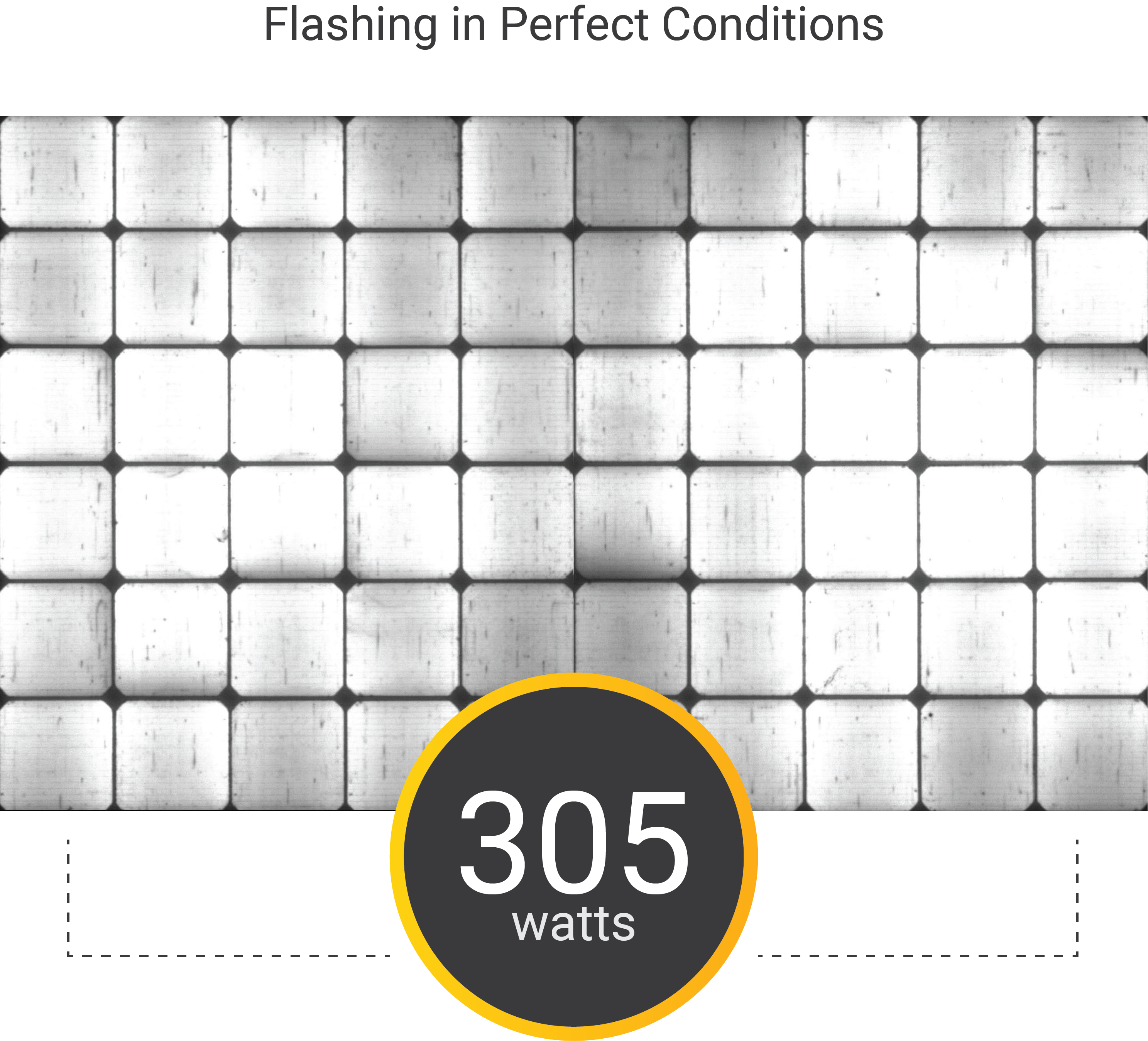

The process of interconnecting solar cells with SmartWire takes EPIQ modules to a new level of performance by maintaining high efficiency even after extreme micro-cracks are induced. The following are Electroluminescent (EL) testing pictures.

Superior Performance

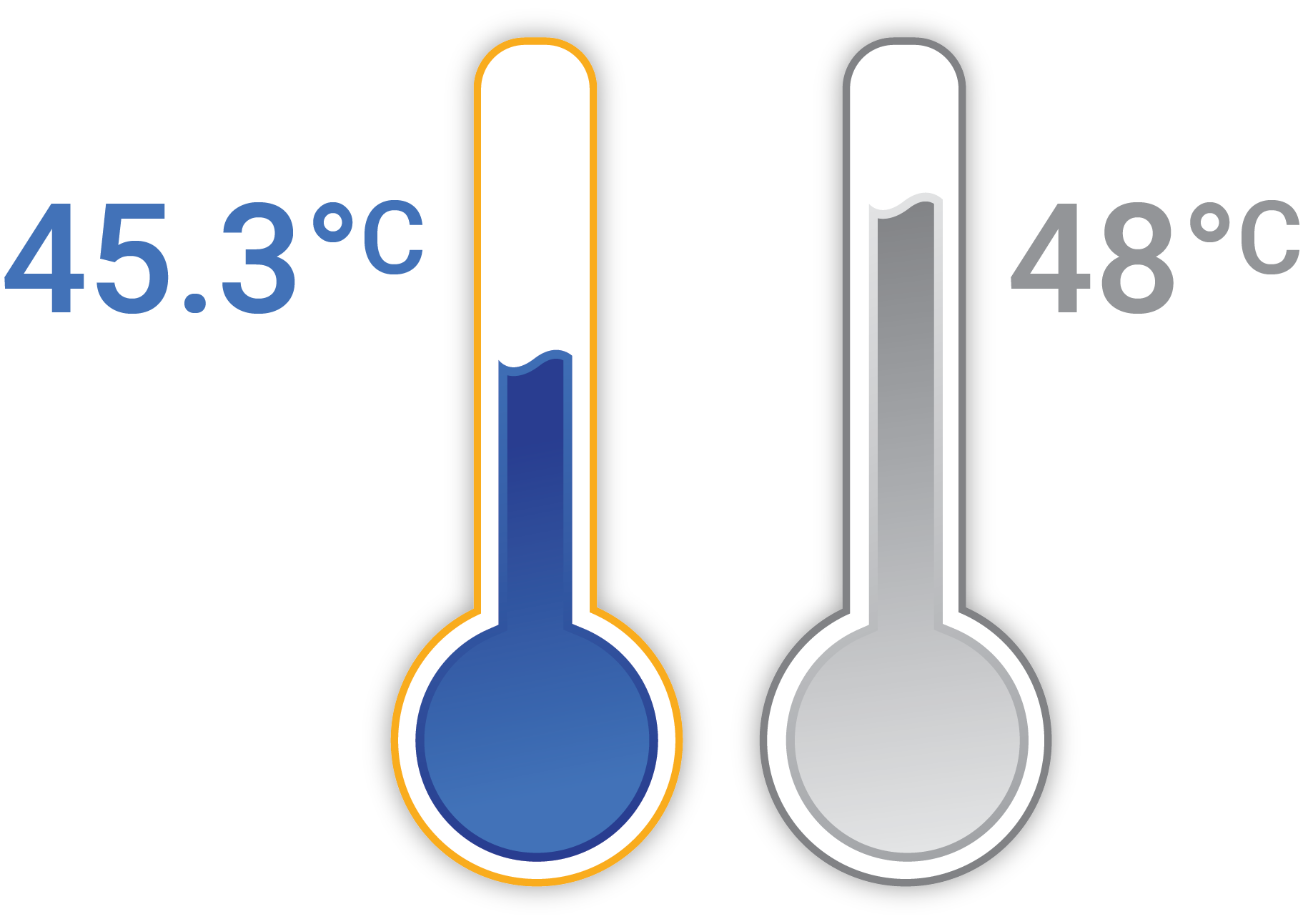

During Sunny Days

Solar module performance is directly related to temperature. As outside temperatures rise, cells heat up, decreasing efficiency. EPIQ modules feature an outstanding Nominal Operating Cell Temperature (NOCT) of 45.3°C utilizing SmartWire Connection Technology

Excellent Performance

In Weak Sunlight

The advanced collection of energy from SmartWire Connection Technology, interacting with the internal reflectivity from mono-crystalline PERC cells; ensures significant energy performance even during cloudy days.

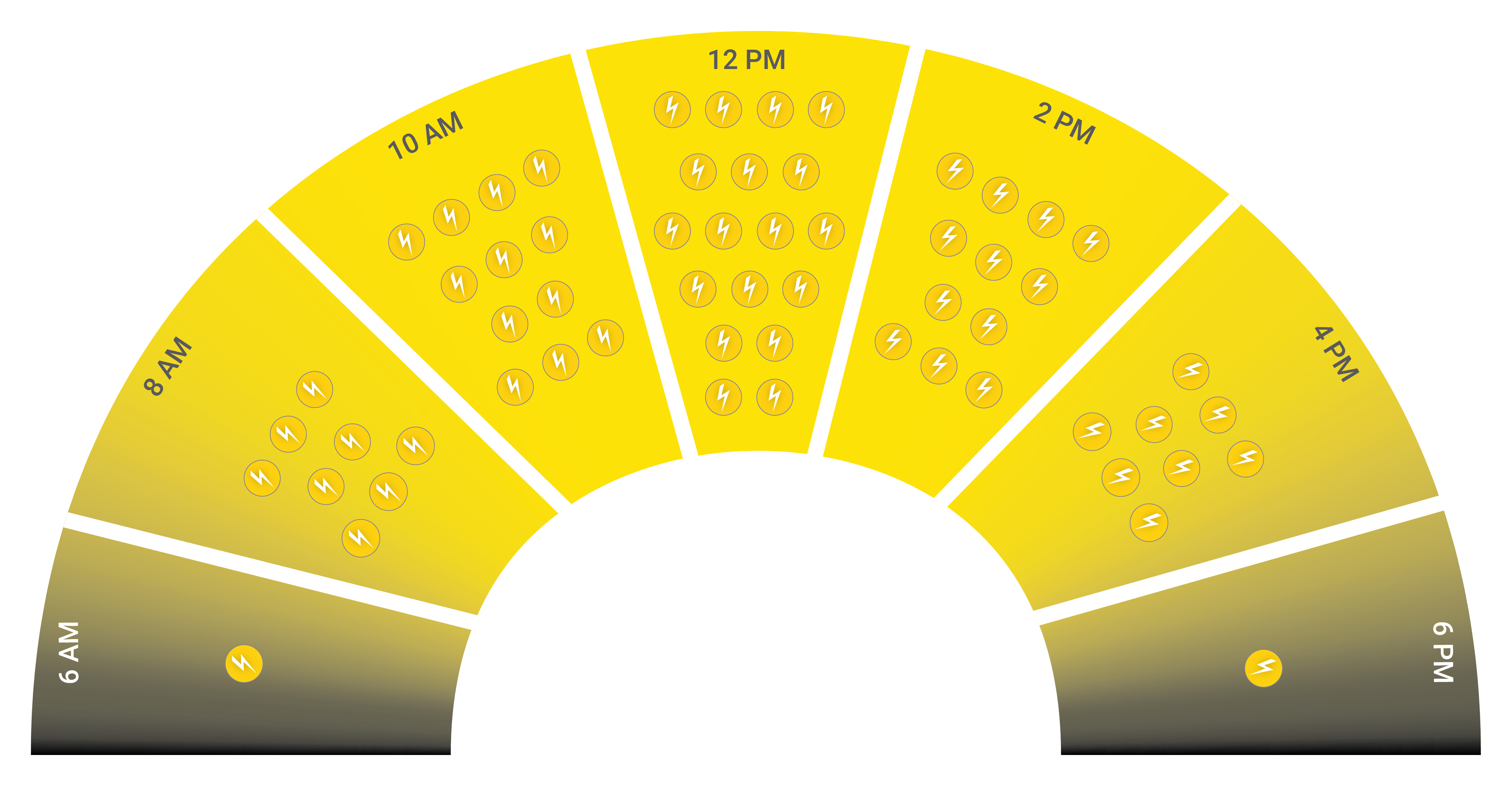

Generate More Power

Through-Out The Day

EPIQ modules achieve a higher energy production through-out daytime hours, by combining SmartWire light absorption properties and the inherent advantages of PERC technology & HJT technologies.

Enhanced Linear

Warranty

Every EPIQ module is manufactured with the highest standards and superior materials to perform longer than conventional panels in the market.

View & download the

SolarTech Universal, LLC. © 2021 - EPIQ is a registered trademark of SolarTech Universal.

The SmartWire Connection Technology (SWCT®) is a proprietary, patented technology developed and solely owned by Meyer Burger (Switzerland) Ltd, Schorenstrasse 39, 3645 Gwatt (Thun), Switzerland.